Many engineers wonder if there’s an answer to their gear noise problems. The answer is “yes”: over the last four decades of manufacturing custom precision plastic gears, Enplas has consistently solved the varied gear noise issues that customers have presented.

The Noise Reduction Process

Enplas follows a time-proven process to reduce noise in customers’ gears. Each step includes Enplas’s impeccable execution, craftsmanship, and scientific expertise.

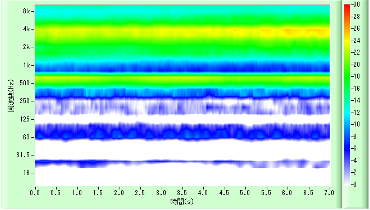

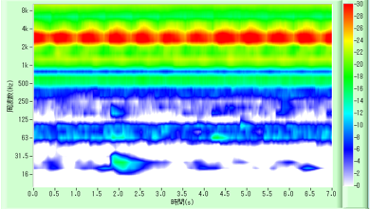

I. Gear Noise Measurement and Analysis

Enplas accurately measures and diagnoses the level of the noise and its cause by analyzing the entire actuator. An environment similar to the actual application is maintained; external noise interference is eliminated.

II. Gear and Gear Train Design

Enplas designs gears and gear trains to optimize the entire gear operation. Material choice, tooth design, and gearbox structure are critical considerations, among many others.

III. Quality Gear Manufacturing

Enplas conducts high-technology toolmaking and scientific molding to ensure consistent mass production. True roundness, surface roughness, and other parameters could affect gear noise level.

Below are a few examples of the types of low-noise gear successes that Enplas’ engineers have made possible for its clients.

Example 1:

“Can I reduce noise in my planetary gears?”

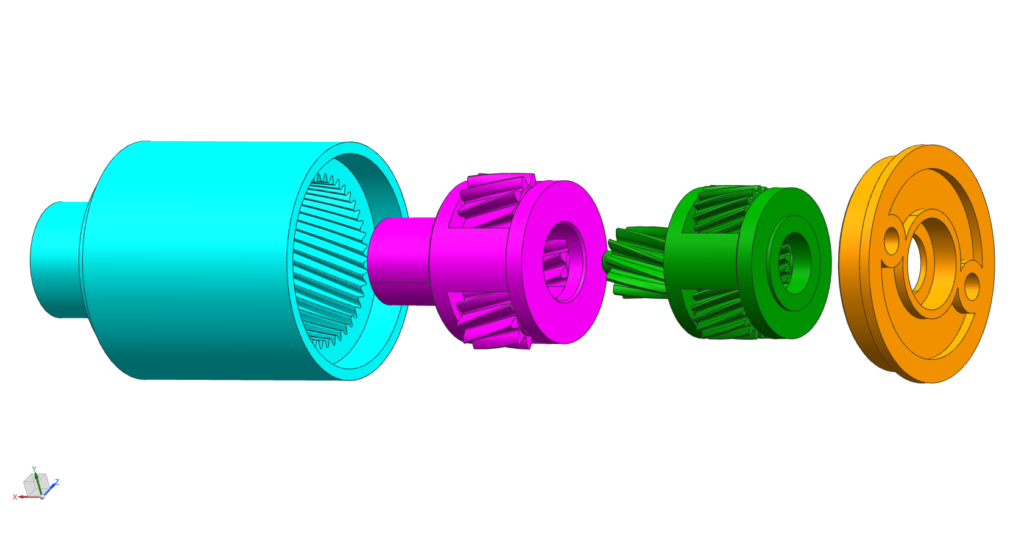

Planetary gears contain mutually-reliant components: the multiple gears, and the outer gearbox. One affects the other; therefore, attentive design and manufacturing of the entire gearbox is necessary to reduce noise.

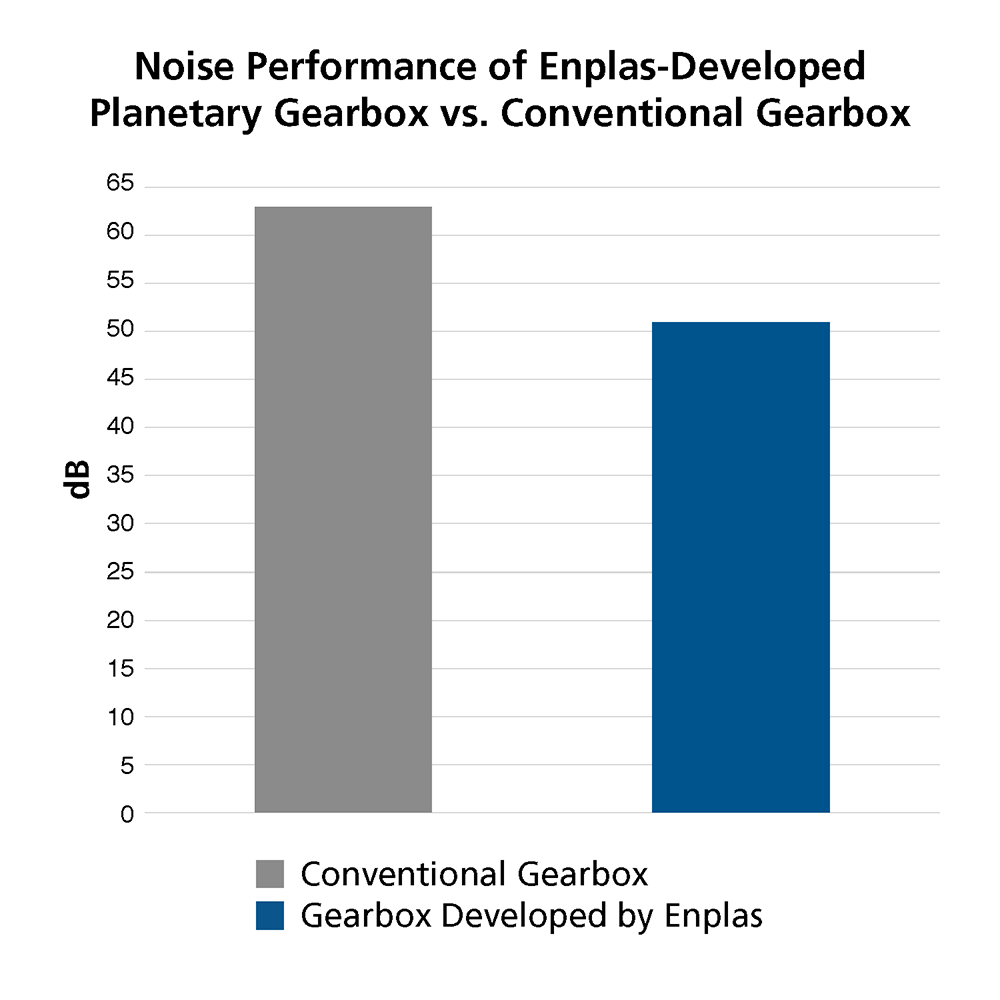

A gearbox developed by Enplas lowered noise output by 12 dB over conventional gear boxes with:

- A uniquely designed structure that reduces transmission of noise and vibration from the internal gears to the external gearbox.

- Precisely manufactured plastic gears (with attention given to roundness, surface roughness, and tooth profile).

EXAMPLE DATA

Data Measurement Parameters:

- Output Torque: 0.3Nm

- Input RPM: 3,000

- Gear Ratio: 18

- Application: Automotive

HEAR IT FOR YOURSELF

NOISE FROM A CONVENTIONAL PLANETARY GEARBOX

NOISE FROM ENPLAS CUSTOMIZED GEARBOX

Enplas has the design know-how to convert your planetary gear design into a low noise gearbox that meets your required noise criteria. To have an Enplas engineer consult with you on your planetary gear and gearbox design, be it for power lift gate (power backdoor), electric blinds and shades, robotics, or other application, contact us today. Or learn more from our downloadable PDF, “Enplas Plastic Gears: Low Noise Solutions.”

Example 2:

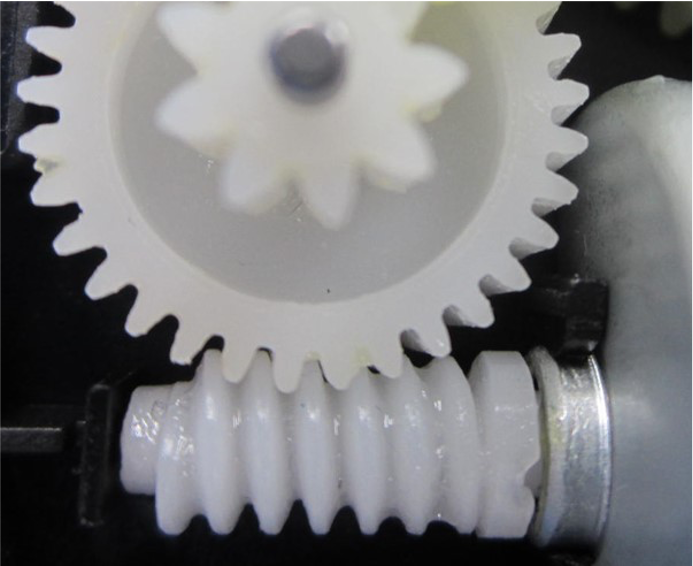

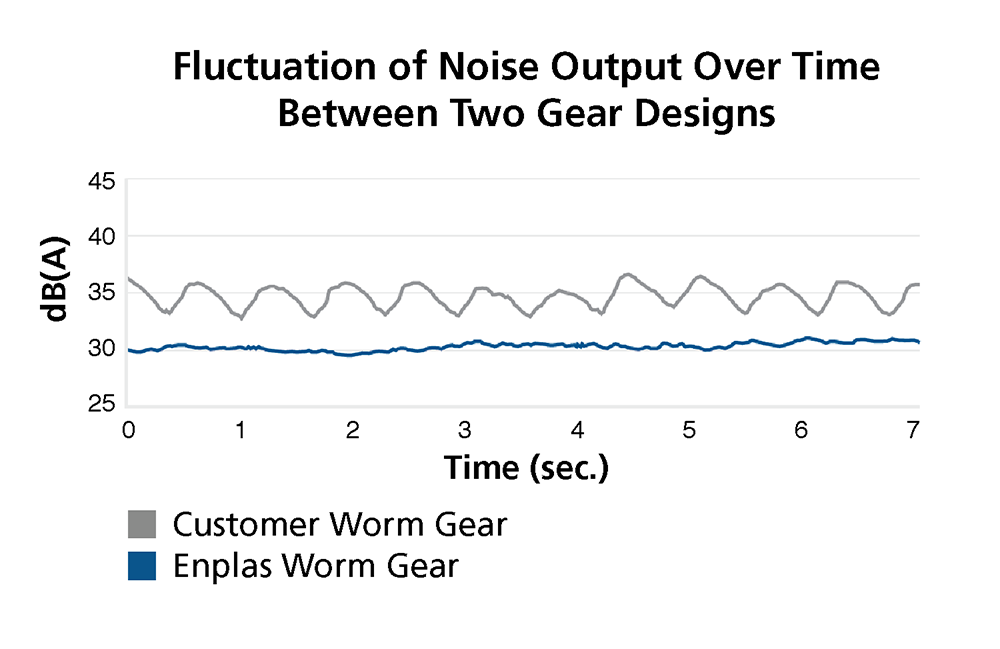

“My worm gear makes cyclic noises. Is it possible to eliminate the ‘peak’ noise?”

Unwanted cyclic noise in worm gears can be reduced. As with the planetary gears above, gear noise depends heavily on gear design and gear train structure, as well as precision manufacturing.

The solutions to worm gear noise issues include:

- Gear design improvement

- Optimization of the entire gear train

- Improved gear precision

- Reduction of gear surface roughness

- Improved roundness precision

EXAMPLE DATA

In this example, a customer’s worm gear made “high peak” sounds at every cycle of gear rotation. Enplas analyzed the source of the noise and manufactured new plastic worm gears that eliminated the cyclic noise.

Data Measurement Parameters:

- Output Torque: No load

- Input RPM: 2,500 RPM

HEAR IT FOR YOURSELF

NOISE FROM A CUSTOMER’S WORM WHEEL GEAR

NOISE FROM AN ENPLAS LOW-NOISE WORM WHEEL

Do you have a noise issue that needs to be identified? Enplas can identify the source of noise in your gears and consult with you on gear design solutions. Contact us for more information, or learn more from our downloadable PDF, “Enplas Plastic Gears: Low Noise Solutions.”

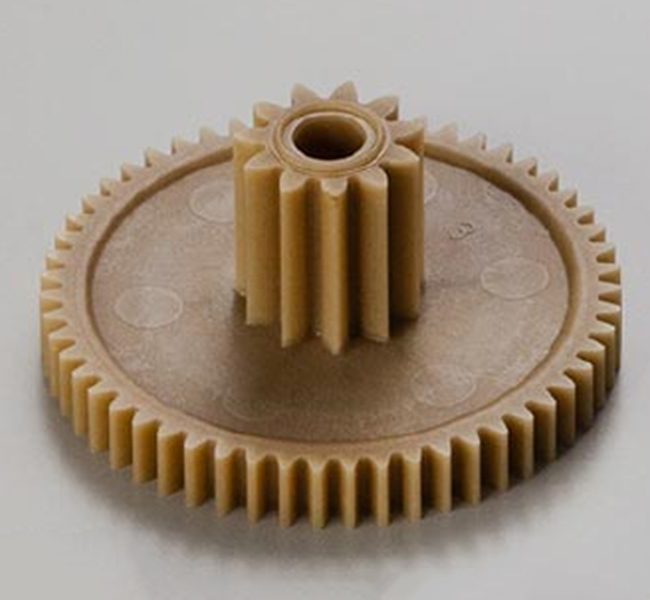

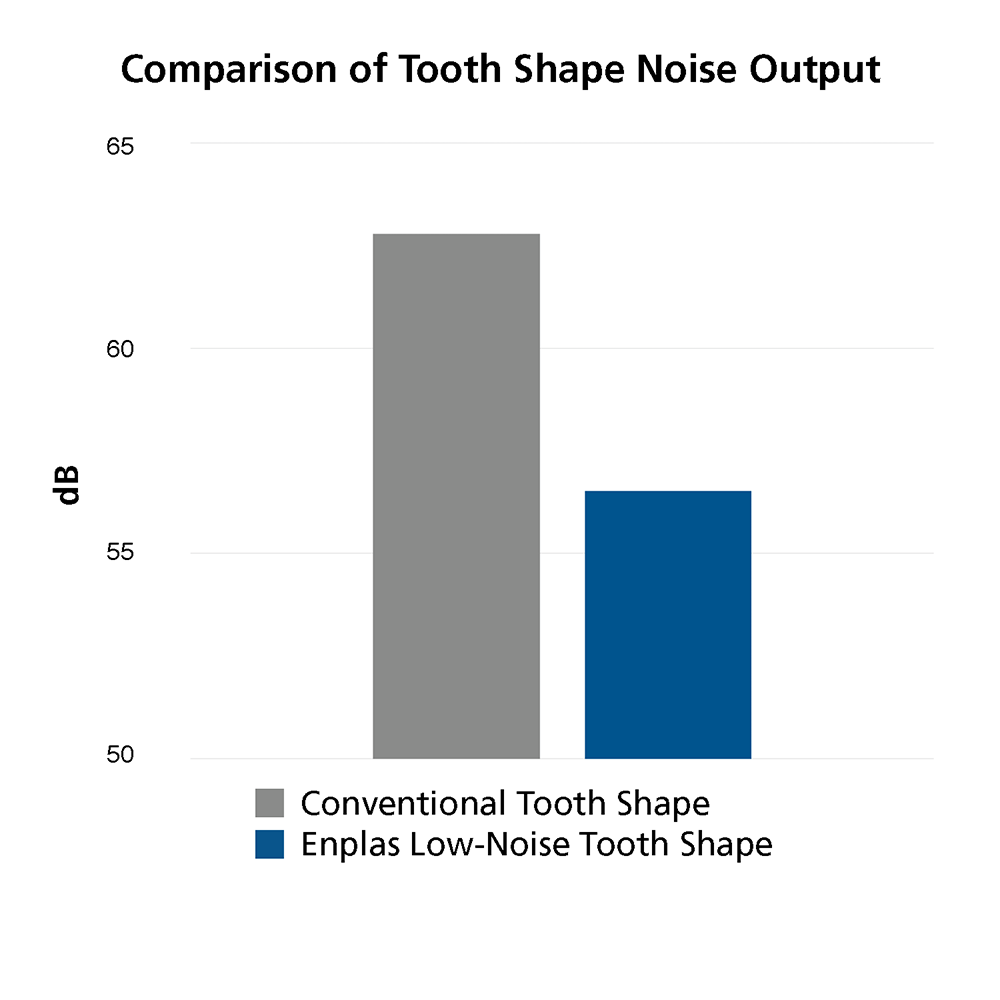

Example 3:

“How can I reduce noise in my spur gears?”

Spur gear noise can affect industries as diverse as automotive, printing, medical, consumer electronics, and more. There are a vast array of causes for spur gear noise. Enplas uses state-of-the-art equipment and establishes the appropriate environments to measure the effects of individual parameters on gear noise. These parameters include tooth profile, roundness, roughness, material property, and tolerance.

In order to diagnose the multitudes of gear noise issues we receive, Enplas analyzes the entire actuator. When our diagnosis confirms that noise is originating from the gears and not another source, the solutions might include:

- Improvement of a single gear

- Optimizing the gear train (such as changing the combination of gear type, gear size, gear ratio, etc.)

- Improvement of the gearbox

- Other

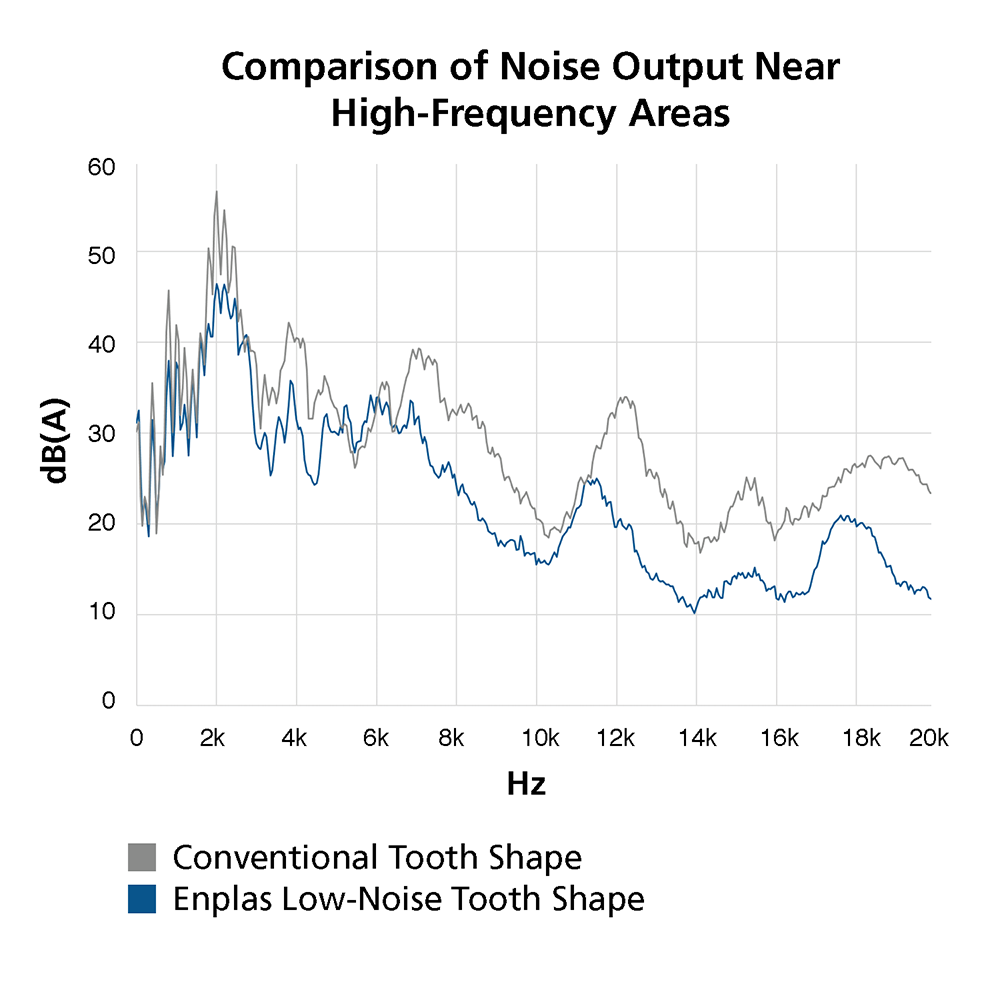

In this example, Enplas made improvements to just one parameter: tooth shape. Designing critical areas to the right shape (in this example, the gear tooth), identifying the noise source, and precision manufacturing the gear to design can all make a noticeable impact on noise reduction.

EXAMPLE DATA

Data Measurement Parameters:

- Output Torque: 0.7Nm

- Input RPM: 1,000 RPM

- Gear Ratio: 5 (=30/12)

Gear Features:

- Gear Module: 1

- Material: POM

- Application: Automotive

HEAR IT FOR YOURSELF

NOISE FROM A CONVENTIONAL SPUR GEAR

NOISE FROM AN ENPLAS SPUR GEAR

Enplas is one of the only custom plastic gear engineers in the industry with the sophisticated equipment required to conduct noise, vibration, and harshness (NVH) analyses on gear units with high degrees of accuracy. Our engineers interpret the results and reference our extensive knowledge and expertise to design gears and gear trains to reduce the noise. Enplas will manufacture custom plastic gears that satisfy noise thresholds and ensure quality, consistent mass production.

Enplas’s in-house expertise, broad proprietary knowledge, real-life testing processes, and scientific engineering mean quality prototyping and mass production at the levels our clients demand. Have a project that Enplas can help with? Contact us today.